Through the provision of various industrial machines,

we contribute to the manufacturing of materials essential to daily life.

We handle a wide range of industrial machines necessary for the production of films, resins, fibers, carbon fibers, secondary batteries, and environmental equipment. To meet our customers' diverse needs, we provide high-quality equipment utilizing the latest technologies, contributing to the development of various industries.

Division Policy

Leveraging our extensive experience in industrial machine implementation support, we will continue to propose optimal solutions to our customers.

As environmental awareness grows across various industries in the pursuit of a decarbonized society, we will focus on providing high-value proposals and handling new environmental-related products.

Division Advantages

-

Extensive network built through years of experience

Extensive network built through years of experience

-

Strong trust from manufacturers based on early information gathering abilities and coordination skills

Strong trust from manufacturers based on early information gathering abilities and coordination skills

-

Provision of insights and advice gained from supporting the implementation of diverse industrial machinery

Provision of insights and advice gained from supporting the implementation of diverse industrial machinery

Key Initiatives

-

Machinery Department

We provide optimal proposals tailored to customers’ needs and challenges for factory equipment used in manufacturing various materials and raw materials, including films, resins, fibers, carbon fibers, water treatment membranes, secondary batteries, and pharmaceuticals. With growing demands for environmental compliance, we are actively handling environmental products such as hydrogen-related equipment and distillation units necessary for recycling processes.

Product Portfolio

-

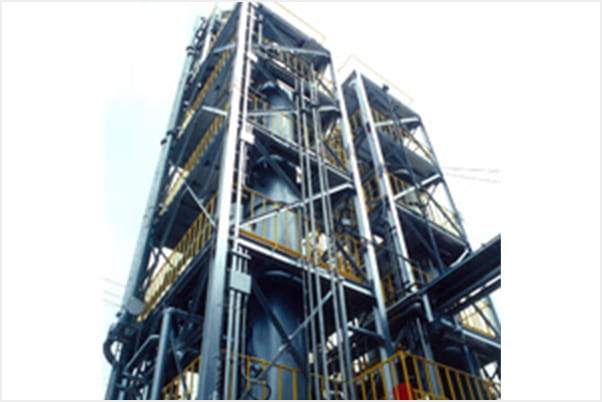

Distillation Equipment

Our distillation methods and distillation/rectification equipment and fractionating systems are designed to be most economical throughout the entire process, taking into account scientific efficiency, thermal recovery rate equipment efficiency, economic efficiency, and operability, based on our long-accumulated various know-how and data.

-

Unit-Type Solvent Recycling System: Echo Challenger

The Echo Challenger enables highly efficient operation from start to completion with a one-touch process using raw liquid preparation. Equipped as standard with an agitator and various safety devices, it features an optimal design that ensures a compact installation space and low cost through unitization. Additionally, we offer the option to manufacture a continuous-type model upon request.

-

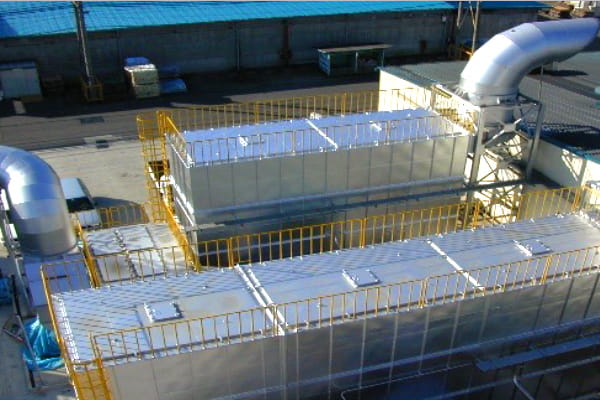

“Bellaria®” High-Performance Deodorization System

The Bellaria® High-Performance Deodorization System is an innovative deodorizing unit with unprecedented adsorption capability. It utilizes a proprietary deodorizing agent developed with a unique formulation tailored to different odors, with magnesium silicate hydrate (a natural porous clay) as its main component. The deodorizing agent is regenerated by our partner company and can be reused repeatedly, ensuring a waste-free operation.

-

Bag Filter

The Bag Filter supports both the pulse-jet method and reverse-shaking method, and can be manufactured with either cylindrical filter fabric or pleated cartridge-type filter fabric. It achieves outstanding dust collection performance through the adoption of a specially designed baffle, a new pulse tube, a low-pressure pulse system, and a vertical filter fabric adjustment mechanism. Designed and manufactured to meet customer-specific requirements, the bag filter can be combined with a variety of peripheral equipment—hazardous gas removal systems, cooling systems, and pre-coat systems—to effectively handle high temperatures, high humidity, and adhesive dust.

-

Pipe Filter

The Pipe Filter is designed to remove liquid particles that cause issues in other processes or contribute to environmental pollution, such as air contamination. These particles, in the form of mist (particle size of approximately 0.5μm to 10μm), are generated by steam condensation or liquid sprays. By effectively eliminating these mist particles, the Pipe Filter helps prevent process disruptions and environmental hazards.