|

|

|

|||||||||||||||

FEATURE

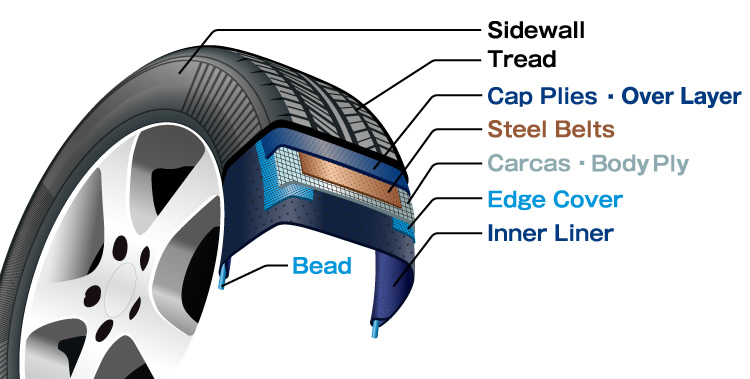

Izumi is able to produce a liner specifically needed for all parts of the tire production. Our main features that we can offer are:

- Easy Release Properties

- Anti-fraying Edges

- Anti-wrinkle

- Antistatic Liners

All manufacturing can be adjusted to meet our customer's needs such as the stiffness or flexibility of the liner. By using a release liner suitable for the process, we can help reduce your loss rate and decrease waste. Izumi's liners have been proven to increase cost savings, productivity and improve tire production. Our durable liners can be used repeatedly which leads to lower costs over the long-term. Custom length and width can be designed and manufactured to meet your needs and requirements.

It is also possible to customize the coloring and install a lead cloth.

MANUFACTURING PROCESS

Physical properties table

| Item | FWF01 | N2M01 | * T-AN5040 R&B |

PL6010 | T1045 | N2595 | |

|---|---|---|---|---|---|---|---|

| Application Area |

Tread | ○ | ○ | ||||

| Cap Plies | ○ | ○ | ○ | ||||

| Steel Belts | ○ | ○ | ○ | ○ | |||

| Carcas/Plies | ○ | ○ | ○ | ○ | |||

| Inner | ○ | ○ | ○ | ||||

| Side Wall | ○ | ○ | ○ | ○ | |||

| Thickness | 0.42 | 0.25 | 0.32 | 0.68 | 0.24 | 0.51 | |

| Weight(g/m2) | 445 | 355 | 205 | 240 | 145 | 300 | |

| Tensil Strength (N/3cm) |

Warp | 800 | 950 | 1580 | 760 | 785 | 1990 |

| Weft | 665 | 950 | 920 | 865 | 980 | 850 | |

| Tensil Strength(<x) | Warp | 60 | 135 | 35 | 55 | 35 | 35 |

| Weft | 36 | 135 | 30 | 25 | 30 | 25 | |

| Bending Resistance of Weft (mN) |

69.5 | 22.0 | 1.4 | 5.2 | 0.3 | 0.1 | |

| 100m roll diameter (3inch Core) |

Diameter | 0.25 | 0.20 | 0.22 | 0.31 | 0.20 | 0.27 |

| 500m roll diameter (3inch Core) |

Diameter | 0.53 | 0.20 | 0.41 | 0.67 | 0.40 | 0.58 |

| Item | TT1000 | TPSF700 | * T-AN5024 R&B |

* NT-1 |

* T-AN6040 R&B |

N2924 | |

| Application Area |

Tread | ○ | |||||

| Cap Plies | |||||||

| Steel Belts | ○ | ○ | ○ | ||||

| Carcas/Plies | ○ | ○ | ○ | ○ | |||

| Inner | ○ | ○ | |||||

| Side Wall | |||||||

| Thickness | 0.56 | 0.60 | 0.46 | 0.61 | 0.21 | 0.6(1.1) | |

| Weight(g/m2) | 390 | 230 | 280 | 330 | 175 | 240(490) | |

| Tensil Strength (N/3cm) |

Warp | 3350 | 960 | 1440 | 1040 | 545 | 1120(3200) |

| Weft | 1230 | 960 | 2350 | 1265 | 960 | 720 | |

| Tensil Strength(<x) | Warp | 40 | 35 | 35 | 35 | 20 | 50 |

| Weft | 20 | 20 | 25 | 25 | 25 | 25 | |

| Bending Resistance of Weft (mN) |

0.8 | 2.5 | 5.0 | 21.0 | 3.3 | 4.0(7.0) | |

| 100m roll diameter (3inch Core) |

Diameter | 0.28 | 0.30 | 0.26 | 0.30 | 0.20 | 0.40 |

| 500m roll diameter (3inch Core) |

Diameter | 0.61 | 0.63 | 0.55 | 0.63 | 0.38 | 0.85 |

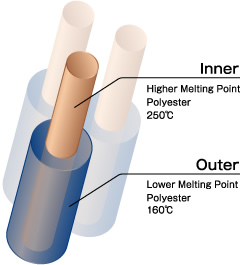

*(made of Sheath-core fiber)

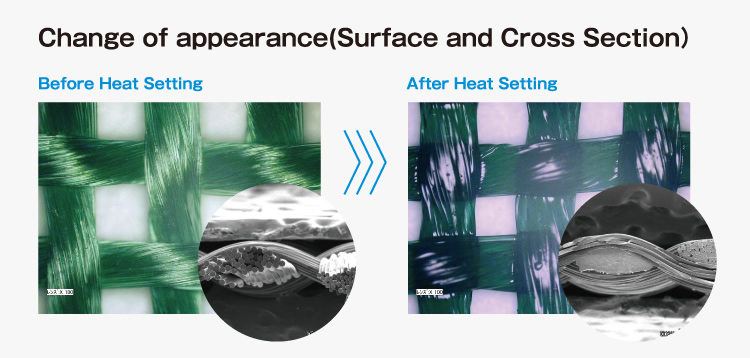

RELEASE LINER made of Sheath-core fiber

Melt and harden reinforce workability and stiffness.

IZUMI Release-Liner has product line up made of Sheath-core fiber. Sheath-core fiber is bi-component pet yarn. When heat setting applied, outer melts then each yarn stick together. This transformation can bring higher stiffness fabric.

|

Copy Right(C) 2003 Izumi Inc. All Right Reserved. |